|

|

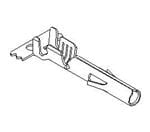

TE Connectivity

794594-4

|

TE Connectivity

4-1108756-1

|

TE Connectivity

T9GV1L14-5

|

TE Connectivity

T9GS5L14-18

|

TE Connectivity

T9GS2L14-12

|

TE Connectivity

T9GV1L24-22

|

TE Connectivity

T9GV2L24-18

|

TE Connectivity

T9GS5L24-9

|

Molex

02-06-1101

|

Molex

02-08-1002

|

| Price |

|

|

|

|

|

|

|

|

|

|

|

| RoHS |

|

|

|

|

|

|

|

|

|

Compliant |

Compliant |

| Lead Status |

|

|

|

|

|

|

|

|

|

Yes |

Yes |