|

|

TE Connectivity

562A067-25/86-0

|

TE Connectivity

382A012-25/42-0

|

TE Connectivity

562A022-100/86-0

|

TE Connectivity

1857925-1

|

TE Connectivity

2828522-6

|

TE Connectivity

2828522-8

|

TE Connectivity

962954-1

|

TE Connectivity

962954-2

|

TE Connectivity

342413-2

|

TE Connectivity

144181-1

|

| Price |

|

|

|

|

|

|

|

|

|

|

|

| RoHS |

|

|

|

|

|

|

|

|

|

|

|

| Lead Status |

|

|

|

|

|

|

|

|

|

|

|

| Transition Type |

|

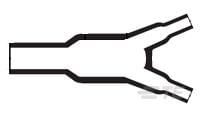

1 to 4 Cables |

Y-Transition |

1 to 4 Cables |

|

|

|

|

|

|

|

| Inside Diameter Range (Body) |

|

26.7 – 55.6 |

.24 – .52 |

.38 – .76 |

|

|

|

|

|

|

|

| Special Requirements |

|

Flame Retarded |

Flame Retarded |

Zerohalogen |

|

|

|

|

|

|

|

| Wire/Cable OD |

|

1.18 |

.35 |

.55 |

|

|

|

|

|

|

|

| Operating Temperature Range |

|

-55 – 105 |

-4 – 140 |

-22 – 221 |

-40 – 125 |

|

|

-40 – 212 |

-40 – 212 |

|

-40 – 212 |

| Material Code |

|

25 |

25 |

100 |

|

|

|

|

|

|

|

| Inside Diameter Range (Leg 3) |

|

.51 – 1.06 |

|

.21 – .37 |

|

|

|

|

|

|

|

| Breakout Angle |

|

45 |

22.5 |

45 |

|

|

|

|

|

|

|

| Wire/Cable Sm Branch OD |

|

.71 |

.18 |

.24 |

|

|

|

|

|

|

|

| Wire/Cable Main Branch OD |

|

.79 |

4 |

.31 |

|

|

|

|

|

|

|

| Adhesive Code |

|

86 |

42 |

86 |

|

|

|

|

|

|

|

| Material |

|

Modified Elastomer |

Modified Elastomer |

Modified Polyolefin |

|

|

|

|

|

|

|

| Inside Diameter Range (Leg 4) |

|

.51 – 1.06 |

|

.21 – .37 |

|

|

|

|

|

|

|

| Inside Diameter Range (Leg 2) |

|

.51 – 1.06 |

.13 – .26 |

.21 – .37 |

|

|

|

|

|

|

|

| Power Cable Accessory |

|

No |

No |

No |

|

|

|

|

|

|

|

| Number of Branches/Legs |

|

4 |

2 |

4 |

|

|

|

|

|

|

|

| Molded Part Type |

|

Transition |

Transition |

Transition |

|

|

|

|

|

|

|

| Adhesive Pre-Coat |

|

Yes |

Yes |

Yes |

|

|

|

|

|

|

|

| Inside Diameter Range (Leg 1) |

|

.51 – 1.06 |

3.3 – 6.6 |

.21 – .37 |

|

|

|

|

|

|

|

| Product Type |

|

Molded Part |

Molded Part |

Molded Part |

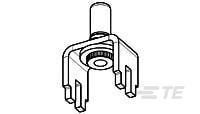

Contact |

|

|

|

|

|

|

| Material Systems Code |

|

25 |

25 |

100 |

|

|

|

|

|

|

|

| Government Qualified |

|

No |

No |

No |

|

|

|

|

|

|

|

| Adhesive Options |

|

/86 Precoat |

/42 Precoat |

/86 Precoat |

|

|

|

|

|

|

|

| Fluid/Chemical Resistance |

|

Long-term exposure at elevated temps |

Long-term exposure at elevated temps |

Occasional exposure to fluids |

|

|

|

|

|

|

|

| Size Code |

|

67 |

12 |

22 |

|

|

|

|

|

|

|

| Color |

|

Black |

Black |

Black |

|

Blue |

Black |

|

|

|

|

| Adhesive Type |

|

High Performance Pre-Coat Adhesive |

General Purpose Pre-Coat Adhesive |

High Performance Pre-Coat Adhesive |

|

|

|

|

|

|

|

| Molded Part Shape |

|

One to Four Cables |

Y Shape |

One to Four Cables |

|

|

|

|

|

|

|

| Pliancy |

|

|

|

Flexible |

|

|

|

|

|

|

|

| Emission Features |

|

|

|

Halogen-Free |

|

|

|

|

|

|

|

| Flammability |

|

|

|

Low Fire Hazard |

|

|

|

|

|

|

|

| Contact Current Rating (Max) |

|

|

|

|

50 |

|

|

|

|

|

|

| Termination Method |

|

|

|

|

Soldering |

|

|

Crimp |

Crimp |

Crimp |

Crimp |

| Number of Positions |

|

|

|

|

4 |

|

|

|

|

|

|

| Connector Mounting Type |

|

|

|

|

Board Mount |

|

|

|

|

|

|

| Connector & Contact Terminates To |

|

|

|

|

Wire & Cable |

Bus Bar |

Bus Bar |

|

|

|

|

| Connector System |

|

|

|

|

Cable-to-Board |

Wire-to-Bus Bar |

Wire-to-Bus Bar |

|

|

|

|

| Contact Base Material |

|

|

|

|

Copper Alloy |

Copper |

Copper |

|

|

|

|

| Contact Size |

|

|

|

|

8 |

9.52 |

9.52 |

|

|

|

|

| PCB Mount Orientation |

|

|

|

|

Vertical |

|

|

|

|

|

|

| Circuit Application |

|

|

|

|

Power |

|

|

|

|

|

|

| Contact Style |

|

|

|

|

Pin |

CROWN BAND |

CROWN BAND |

|

|

|

|

| Voltage Drop |

|

|

|

|

35 |

|

|

|

|

|

|

| Contact Plating Material |

|

|

|

|

Silver over Nickel |

Tin |

Tin |

|

|

|

|

| Current Rating |

|

|

|

|

50 |

250 |

250 |

|

|

|

|

| Contact Length |

|

|

|

|

|

50.8 |

50.8 |

|

|

|

|

| Housing Material |

|

|

|

|

|

Thermoplastic |

Thermoplastic |

|

|

|

|

| Packaging Method |

|

|

|

|

|

Package |

Package |

Reel |

Reel |

Reel |

Reel |

| Insulation Material |

|

|

|

|

|

Thermoplastic |

Thermoplastic |

|

|

|

|

| Wire Size |

|

|

|

|

|

168000 |

168000 |

1 – 2.5 |

1.5 – 2.5 |

.65 – 2 |

1 – 3 |

| UL Rating |

|

|

|

|

|

Recognized |

Recognized |

|

|

|

|

| Mounting Retention |

|

|

|

|

|

No |

No |

|

|

|

|

| Connector Style |

|

|

|

|

|

Receptacle |

Receptacle |

|

|

|

|

| Hot Pluggable |

|

|

|

|

|

No |

No |

|

|

|

|

| UL Flammability Rating |

|

|

|

|

|

UL 94V-0 |

UL 94V-0 |

|

|

|

|

| Mounting Retention Type |

|

|

|

|

|

Crimp |

Crimp |

|

|

|

|

| Wire Insulation Diameter |

|

|

|

|

|

|

|

6 |

.087 – .118 |

2.4 – 3.5 |

.079 – .118 |

| Wire Size Search |

|

|

|

|

|

|

|

15 |

15 |

15 |

15 |

| Interface Plating |

|

|

|

|

|

|

|

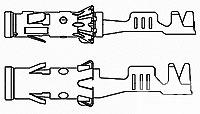

Tin (Sn) |

Silver (Ag) |

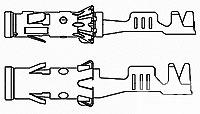

Tin (Sn) |

Tin (Sn) |

| Packaging Quantity |

|

|

|

|

|

|

|

1500 |

1500 |

2500 |

3500 |

| Wire Type |

|

|

|

|

|

|

|

Copper |

Copper |

Copper |

Copper |

| Receptacle Style |

|

|

|

|

|

|

|

180° |

180° |

180° |

180° |

| Mating Pin Diameter |

|

|

|

|

|

|

|

4 |

4 |

|

|

| Crimp Type |

|

|

|

|

|

|

|

F-Crimp |

F-Crimp |

F-Crimp |

F-Crimp |

| Terminal Transmits |

|

|

|

|

|

|

|

25 – 40 A (Power) |

25 – 40 A (Power) |

0 – 24 A (Low Power) |

0 – 24 A (Low Power) |

| Terminal & Splice Style |

|

|

|

|

|

|

|

Socket |

Socket |

Receptacle |

Receptacle |

| Primary Locking Feature |

|

|

|

|

|

|

|

Locking Lance |

Locking Lance |

Locking Lance |

|

| Contact Termination Area Plating Material |

|

|

|

|

|

|

|

Tin (Sn) |

Tin (Sn) |

Tin (Sn) |

Tin (Sn) |

| Agency/Standard |

|

|

|

|

|

|

|

|

LV214 |

|

|

| Sealable |

|

|

|

|

|

|

|

|

Yes |

No |

No |

| Customer Preferred Contact |

|

|

|

|

|

|

|

|

|

No |

No |

| Mating Tab Thickness |

|

|

|

|

|

|

|

|

|

|

.64 |

| Typical Current Rating |

|

|

|

|

|

|

|

|

|

|

15 |

| Mating Tab Width |

|

|

|

|

|

|

|

|

|

|

3 |